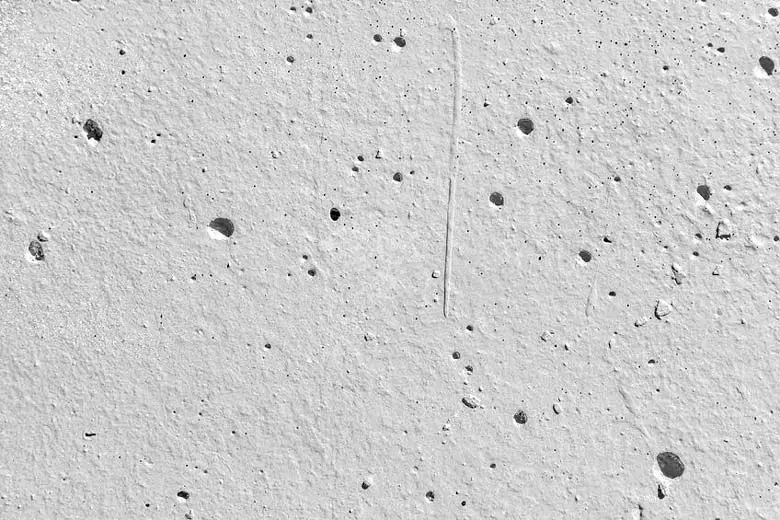

Tiny holes in concrete walls aren’t uncommon. There are times when they can make a wall look unique. But in many cases, they’re often unwanted and out-of-place.

Some concrete walls have holes in them because of trapped air bubbles that escape to the surface of the concrete. During mixing, some air bubbles form in the cement. As the cement sets, the shrinkage forces the air spaces out of the wall, leaving behind cavities called bugholes.

This article looks at how these holes form in a concrete wall. It also offers some tips to prevent big holes from forming in your new concrete wall.

Table of Contents

How Air Gets Trapped in Concrete

Incomplete Vibration of the Concrete

Freshly poured concrete already has numerous air bubbles. If construction workers don’t eliminate these bubbles, they’ll create airspaces that can weaken the resulting surface after the concrete dries.

The best way to get rid of these airspaces is by properly vibrating the concrete. When the concrete mix is not sufficiently vibrated, some voids will remain in the concrete.

You’ll also notice that improper vibration causes the concrete to over-consolidate, which leads to segregation. In this case, some aggregate materials separate from the rest of the mix, reducing the structure’s durability and strength.

Incorrect Mix Proportions

It is important to have the right measurements of materials in your mixture if you want a consistent and solid wall. A mix design that produces a stiff concrete mixture will most likely yield voids after consolidation.

Release Agents

Release agents prevent the concrete mixture from sticking to the form structure. Broadly speaking, there are two types of release agents:

- Chemically reactive agents

- Barrier release agents

Although barrier release agents are cheaper than chemically reactive agents, they are prone to creating air pockets in your concrete.

Form Material

The material of the underlying formwork structure also affects how effectively air and water bubbles are released from the mixture. Non-permeable forms such as steel can prevent the movement of air between the concrete and the form structure, increasing the chances of bughole formation.

Problems Associated With Holes in Concrete

- Poor Aesthetics. The most frontline problem with holes in a concrete wall is that they don’t look that good. It’s frustrating to get bugholes, if you’re going for a smooth wall finishing.

- Loss of Durability. A few holes are probably not going to cause any structural weaknesses on the wall. But if the wall has several bugholes, it’s said to be honeycombed. A wall that is honeycombed loses its ability to resist water entry. In addition, a high percentage of air gaps in the wall reduces its strength and therefore its durability.

- Problems During Painting. Holes in the concrete wall can make the painting of the wall difficult because the surface has to be as smooth as possible. They lead to paint wastage and an overall unsatisfying appearance.

How To Prevent Holes From Forming in a Concrete Wall

Proper Consolidation

Consolidation is the process that eliminates air bubbles from a concrete mixture by vibration. In this process, the mixture is agitated by high-frequency vibrations that cause random movement in the particles.

During an effective and proper consolidation process, the concrete vibrates until it expels enough air out of the mixture. As a result, the concrete gets an even consistency.

Remember to put the vibrator as close to the form as possible, but do not let it touch the mix. You should also avoid using a high amplitude vibration during consolidation.

Although it’s practically difficult to get rid of all air voids, the consolidation process has to aim for the elimination of at least 5%of the internal air in the mixture. Any more consolidation beyond that would not make a significant change on the after-results. In fact, it would simply raise the costs.

Only Use Permeable Forms

Non-permeable forms are prone to retaining air spaces because they require more vibration to bring the air to the surface.

Permeable forms, however, eliminate these holes by allowing the air to move through the form itself. Use a form that’s smooth, free from holes, dents, and build-up. In addition, it’s important to choose chemically reactive agents to speed up the process of air elimination.

If there is an excess release agent on the form, it can create bubbles that will increase the number of bugholes in your concrete wall. Always wipe off the excess and ensure the form is free from moisture even before you apply the release agent.

Choose a Balanced Mix Design

Stiff mixtures often need a lot of power to consolidate. But if the mixture is more fluid, it’s easier to free it of air through vibration.

In general, you can reduce holes in a mixture more effectively by using proper portions of cement, allowing increased flow of the mixture, and avoiding extra amounts of fine aggregate.

Improve Concrete Handling

You can drastically reduce the number of holes in the wall by using an appropriate speed while pouring the concrete into the form. If you pour it too fast, the air doesn’t get enough time to escape.

You should also minimize the distance between the concrete’s point of discharge and the form. If this distance is large, the impact can increase the amount of air entrapped in the concrete.

How To Fix Existing Holes in a Concrete Wall

If bugholes have already occurred on your concrete surface, there are two ways to repair them.

You can fill small voids using a concrete grout in many cases. The type of grout used will vary based on the size and depth of the holes. This Sashco sealant from Amazon is highly effective and easy to use.

If the bugholes are fairly large, you might want to use your patching material to fill them in.

- Start by outlining the area around the hole with a deep saw cut of around three-quarters of an inch (1.9 cm) deep. Ensure that the cut is free of defective concrete. Clean the cut by removing loose material and dust.

- Use water to make the patch area damp. Do this for 6 inches (15.24 cm) around the patch as well. Form your patch material by mixing equal parts of cement, sand, and water until you get a thick mixture. Then, brush the scrub coat into the substrate.

- Using the same materials as the wall concrete, mix a repair mortar. However, don’t use coarse aggregates unless the hole is very large. To maintain aesthetics, you can use a mix of gray and white cement to match the surrounding area of the wall.

- As the scrub coat loses its water sheen, apply the repair mortar. Remember to leave the patch slightly higher than the surrounding area to accommodate for shrinkage.

- Let the patch consolidate for about an hour then do some finishing to match its texture to the surrounding area of the wall. Keep the patch damp for about a week.

Conclusion

Holes normally form in concrete walls due to air spaces that rise to the surface of the wall. It’s majorly due to improper vibration of the concrete, incorrect mix proportions, and using the wrong release agents and form material.

These holes not only ruin the appearance of the wall but also weaken it and make it hard to paint. They can be avoided by carefully selecting materials, and thoroughly supervising the mixing process of the concrete. Pre-existing holes in a concrete wall can be fixed using concrete grout or by preparing a patch mixture for larger holes.