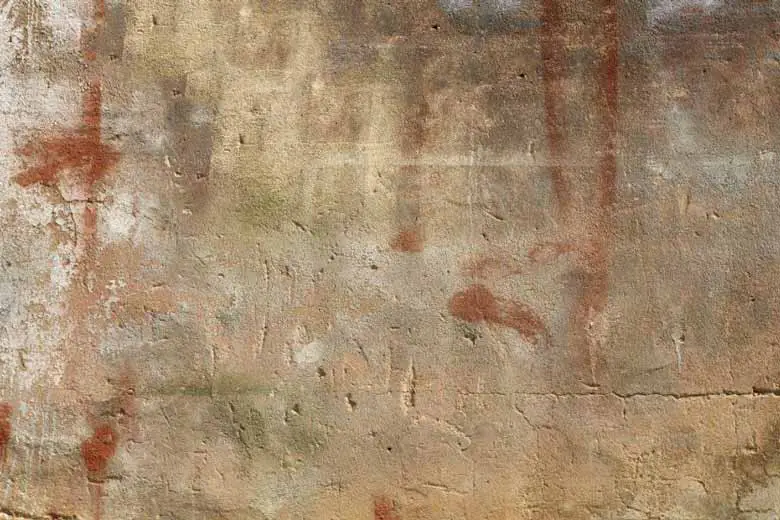

An area of freshly dried concrete can be very pleasing to the eye while also increasing the value of the property where it is laid. When concrete changes color and is no longer uniform, it can greatly reduce its value and pleasing look, which can be a detriment to homeowners and other property entities. This discoloration can appear in a variety of ways and is caused by multiple factors.

Common causes of concrete discoloration are inconsistency in the concrete mixes, water amount, and curing procedure used in different batches of concrete in the same project. Adding calcium chloride to the mixture, using slag cement, or even inaccurate troweling may also cause discoloration.

Knowing what can cause color changes in concrete will allow you to put measures in place to prevent this outcome from occurring. If discoloration has already occurred, there are some steps we can take to maybe bring back that consistent color that everyone loves to see.

Table of Contents

Possible causes for concrete discoloration

Since many elements can be a source of discoloration in concrete, it is important to take into account every possible reason for this circumstance. Sometimes discoloration happens during the time of pouring but may be seen hours or even days later.

Actual color changes in concrete such as blue, green, or yellow are the result of a more environmentally friendly concrete being used called “slag”. This ingredient contains a mixture of recycled materials aimed to reduce the environmental impacts of concrete. This concrete formula tends to produce a bluish and greenish color after about a year. With this in mind, it may be easier to just stay with the traditional concrete mix. Although, if you do not mind color changing concrete, you will save more money using slag.

The most common discoloration sight to see in regular concrete is streaks or blotches that are darker or lighter than the overall concrete color.

Different concrete mixes used in the same project

Inconsistency in the concrete mixture is the most common cause of color changes in concrete. Many people that are new to concrete think it is just a concrete mixture mixed with water, however, there are many different ingredients in the differing types of concrete powders that are available that yield different results.

Using two different brands or suppliers of concrete is ill advised as it will most likely mix together and produce two different colors.

Consistency is key when pouring concrete.

It may seem too fussy or nit-picky but you want the brand, the amount, the ingredients, and everything else to be the same with your concrete to yield the best results.

Inconsistency of the water amount in the concrete mixtures

Water is an important ingredient to concrete and specifically, the amount of water used must continually be consistent with the project until it is complete, or you will end up with that blotchy texture with varying shades.

Also read: What Happens When Concrete Is Too Wet?

If you are tackling this concrete project on your own, make sure to always measure the amount of water you are using with the same amount of concrete mixture, especially if it is a big project that requires multiple batches of concrete blends. You want each of your mixes to include the same ratio of water and concrete to produce that steady and constant color.

Poor Workmanship may cause discoloration

Poor workmanship is an obvious contribution that will create less than desired results. When it comes to pouring concrete there are a few particulars that are important to take into consideration, especially when creating a more permanent structure.

Avoid trowel burning on the concrete. Metal fragments can become embedded in the concrete as a result of trowel burning and this causes spots of dark color.

Uneven curing can also cause discoloration. Hydration is affected by curing and when it is not uniform, causes clashing light and dark colors.

If you are performing this concrete project on your own, take into account the weather at the time of the pour. If it is dry, it may be wise to wet down the material where the concrete will be laid. When rain is present, it may be more painless to wait until conditions improve.

Read more: Concrete Work in the Rain: Is it even possible?

How to prevent concrete discoloration?

We all know the best solution is prevention. Taking this into the context of avoiding color variance in concrete, here are a few tips to keep in mind when planning your next concrete project.

- If you are hiring a concrete finisher, make sure they are a reputable source with a trusted supplier of concrete. You may wish to contact them and ask where they get their concrete from and how long they have been in the business. If they are online, you can read reviews of past customers to avoid being unsatisfied with the job.

- High alkali contents can contribute to discoloration which is why it is important to compare concrete brands to see which has the least of these ingredients.

- Avoid calcium chloride in your concrete mixtures as well. This and other chloride containing chemicals should not be used when trying to avoid discoloration.

- If you are new to concrete pouring, you should not take on a project by yourself before learning as much as you can. Even then it could be very valuable to get help from a friend who is experienced to avoid any unplanned results. You do not want to spend a lot of money on a project you are not satisfied with in the end, especially if the whole neighborhood can see it.

How do you fix discolored concrete?

Let’s say it is too late and your concrete is color changing as we speak. There are some things that can be done to minimize the effects of discoloration on your concrete.

If the discoloration is caused by calcium chloride, some elbow grease may do the job. Use hot water and scrub the concrete thoroughly and allow it to dry. If no improvement is shown after this, a more intense approach may be needed.

A homemade diluted solution of hydrochloric acid can be used as well. Wet the concrete before application and then scrub the acid onto the concrete to clean the discoloration.

There are also products available for purchase that are used to clean concrete and produce a more uniform color. The best concrete cleaners can make even the toughest stains disappear. But sadly, all discoloration can’t be removed by cleaning.

Another solution would be to add another layer of concrete by pouring new concrete over the old concrete. You could also stain the discolored concrete or add a coating to it. While this solution is more pricey, it can do well in the long run.

Painting the concrete might be one of the easiest solutions.

Also read: Acid Staining Old Concrete: Is it a good idea? Plus 10 tips!

Concrete Alternatives

If the concrete has lost its appeal to you by this point, there are alternatives especially when it comes to sidewalks and driveways. Asphalt is cheaper and easier to repair but concrete does last longer. Bricks and blocks last longer than both and are very aesthetically pleasing, but are more expensive overall.