In the 21st Century, concrete is one of the most commonly used building materials. We use it for sidewalks, roads, buildings, and almost anything you can think of. Concrete is widely used because it is extremely versatile and durable, but it doesn’t last forever. This begs the question, what do we do with concrete once it needs to be replaced? Does it get thrown away, or can we recycle it?

Concrete is a recyclable material with no limit on which types can be recycled. Commercially, concrete is removed, crushed, and transported to its new site. For at-home concrete recycling, it is removed, crushed up with a hammer or rented machine, and can be used for either decoration or function.

The list of benefits that come from recycling concrete is just about as long as the list of uses for recycled concrete. This material is not the most environmentally friendly, but it can be if we choose to educate ourselves on the ways we can reuse it rather than remake it.

Concrete Should Be Recycled

If you went to a public school in the United States, it’s almost a guarantee that you’ve heard of the phrase “Reduce, Reuse, and Recycle”. Most people recognize this saying and know to recycle things like cans, bottles, and paper products.

We know recycling small household items is beneficial, but what do we do about bigger things?

In the United States, we calculate how much solid waste is produced yearly and what that waste is. A central component of solid waste in the US is construction and demolition (C&D) waste, accounting for around 25% of waste every year. 70% of C&D waste can be attributed to concrete. (Source)

This alone should convince you of the necessity of recycling concrete. Landfills in the US are being filled as time goes by, and this is dangerous to the environment.

If the waste produced by concrete is not enough to sway you, let’s look at just how much water concrete uses up.

One cubic yard of concrete uses 32 gallons of water and washing a 10-yard concrete truck uses an average of 225.99 gallons of water per wash. (Source)

With the average city block being 330′ by 660′, the average patio being 288 square feet, and driveways being 640 square feet on average, it’s easy to imagine just how much water is used on concrete production every year.

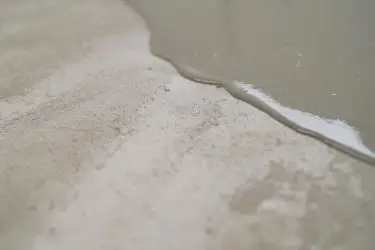

Another way concrete is harmful to the environment is its lack of water absorption. Floods in major cities around the United States are often worsened by the amount of concrete in the area because the concrete blocks excess water from soaking into the ground, causing floods to be bigger and longer-lasting than ever before. Source

The Process Of Recycling Concrete

In spite of all the negative effects of concrete, I do not think we should discontinue using it- I think we just need to be smarter about how we dispose of it.

Commercial sites are where the bulk of concrete waste comes from. The commercial construction industry uses the most water and concrete, and it also disposes of the most concrete.

Thankfully, concrete and all of its elements are recyclable.

- Recycling Washwater: Washwater is the water that comes from washing and cleaning concrete machines and tools. This water is recycled by filtering for large chunks of solid material and then being transported to a water treatment facility where it is treated and put back into a city or natural water source.

- Recycling Solids: Concrete solids are the aggregate materials filtered out of wash water. These materials are recycled first by being separated into coarse and fine elements, after which they are brought to a concrete facility to be reused for making new concrete.

- Recycling Hardened Concrete: Hardened concrete (concrete that has been demolished) is most commonly recycled at the original site. Machines are brought in to crush or grind the concrete up into small components that are used for road foundations, filler, or are brought to a concrete recycling facility.

- Recycling Wet Concrete: Builders commonly make or order more concrete than needed for their projects as a safety precaution, but it often goes unused. This wet concrete is returned to the plant it came from and recycled by either 1. Being used for precast concrete products 2. Being washed into a reclaimed or 3. Being dumped on a demolition site and left to harden so it can be recycled as hardened concrete.

Commercial concrete is and can be recycled easily in all forms, but recycling concrete at home through demolition can pose to be a bit more of a challenge. Thankfully, using recycled concrete components to make new concrete is not the only way to reuse.

The easiest ways to recycle concrete from a residential project are as follows:

- Reusing Concrete: Concrete can be reused for new projects at home if it is broken correctly. You can use large chunks to create a raised fire pit, small chunks as decorative rocks around a house, and refined or ground pieces as the base for a playground.

- Selling Concrete: Selling old concrete is a great way to recycle it. Places like E-bay, Craigslist, and Facebook Marketplace often have listings for old concrete chunks. By selling your concrete you’ll make money and help someone else out at the same time.

- Donating Concrete: The last way to easily dispose of concrete at home is to donate it. Many concrete contractors and landscaping companies will accept old concrete donations- just make sure to call your local company ahead of time to ensure they’ll be able to accept your donation.

Read more: 7 Places You Can Take Concrete To Be Recycled

The Benefits Of Recycling Concrete

By now, you’re pretty much an expert on the effects concrete has on the environment, how it’s recycled, and how it’s reused, but you may be wondering what the long-term benefits are.

- Recycling Concrete Saves Money: Yes, you read that right. Companies and taxpayers alike save money when concrete is recycled and reused rather than discarded. Recycling concrete correctly can save companies over 20% in material costs alone. This increases revenue for private companies and decreases taxes used for reconstruction governmentally (source).

- Recycling Concrete Saves Water: As we went over earlier, concrete production wastes a lot of water, which affects our wallets and the environment. By reusing all forms of concrete, but specifically wash water, we save water. This is good for all parties involved, but especially concrete companies, as they can be charged up to $25,000 for incorrectly disposing of wash water.

- Recycling Concrete Helps The Environment: The environment is easily the area that sees the most benefits from concrete being recycled. When we recycle concrete, landfills are receiving less demolition material, water is being saved, and awareness is raised for how we can better treat the world we live in.