Making concrete powder is a fairly simple process, and anyone can do it by following a basic recipe. Rather than buying the mix, you can learn to create your own!

To make concrete powder, mix cement, aggregate (course gravel, sand, peat moss, or vermiculite), and water together. The mixture is one part water, two parts cement, and three parts aggregate. Mix all ingredients together to form a thick oatmeal consistency.

A typical concrete mix is 10 to 15 percent cement, 60 to 75 percent aggregate, and 15 to 20 percent water in addition with air to ensure your concrete is adaptable in weather. Concrete can be quite particular at times, but the process has been known to work better through careful mixing, checking your consistency, and knowing the different types of ingredients and how to find the best options. Here are some tips and tricks to help you produce the best outcome.

Table of Contents

Knowing Your Ingredients

Water

Fresh, clean water is important and is what determines the strength of your concrete. Impurities in your water can affect the setting time, strength, and can also cause staining, corrosion, and instability. For example, salt water reacts badly against steel, and added sugar into your water prolongs the setting up process.

Overall, human grade water is the best option, without extra chlorides, alkalis, and sulfates. If necessary, tests can be done on your water to ensure it is safe and clean.

Aggregate

Good quality aggregate is clean, strong, hard, and free of any harmful chemicals. A variety of aggregate options are available:

- gravel

- sand

- vermiculite

- peat moss

Aggregate makes up 60 to 75 percent of your mix and will help the durability and life span of the concrete.

Choosing aggregate that is not weathered or porous is crucial to the life and appearance of concrete. More porous gravel will cause air to be trapped within your concrete and make it become unstable, while weathered gravel decays more quickly and compromises the concrete’s life.

Consistent aggregate is also important, and trying to keep your aggregate similar in size will help keep it more smooth and consistent. The more aggregate the thicker the concrete will be. A more cost effective way of mixing concrete is to buy a more course aggregate, although using a more fine aggregate produces a more smooth finish. Source.

Cement

Cement is the binding agent of your concrete and is made of a mixture of limestone and clay materials that have been heated to high temperatures so that it sets up and hardens independently.

In construction, non-hydraulic and hydraulic cement is most common. Non-hydraulic cement can’t harden while it is in contact with water, while hydraulic cement can.

Portland Cement (hydraulic) is used by many and time tested, but there are other cement options.

- Mortar Cement

- Masonry Cement

- Rapid Hardening Cement

- Quick Setting Cement

- Low Heat Cement

- Sulfate Resistant Cement

The stronger cement powder you are able to find, the less water you will need for it to be sturdy cement. You can also buy cement at your local hardware store, and can get it premixed with aggregate. Find the best cement type that works for you specific project.

Air

Air is another component of your concrete that is important. If your concrete will be prone to freezing weather, having small, well-spaced air bubbles in your concrete is good and helps the concrete to adapt and provides spaces for freezing and thawing water to go. This is called entreated air. It also helps the concrete to be more workable when you lay it. You can work air into your cement or buy air-entraining mix.

Mixing And Ratios

Mixing cement seems easy, but doing it carefully can produce better long lasting results. First, mix together the cement and aggregate (your dry mix). After you have made your concrete powder, mixing water in will make your concrete paste! Add a small amount of your dry mix to water, and be sure to mix it well before adding more dry mix. Repeat the process until you have mixed in all your dry mix.

Another way of doing it is to sprinkle your water in gradually. As mentioned previously, the ratio is one part water, two parts cement, and three parts aggregate. Sand can also be added in addition to other aggregate options making the ratio one part cement, two parts sand, three parts aggregate, and a half part of water.

Another ratio to consider is the water/cement ratio. The amount of water in pounds compared to the amount of cement is called the W/C ratio. Your concrete will be strongest at the lowest W/C ratio. Once you have it all mixed, you can see and adjust your consistency.

Getting the Correct Consistency

Concrete that is too runny will reduce the compression strength of the concrete, thus causing it to deteriorate much more quickly over time. While on the other hand, concrete without enough water will be hard to work into the correct shape.

A great way to check your consistency is by conducting a slump test, which requires a slump cone. But if that is not an option, using a big cup does the trick. Cut a hole in the top of the cup, set it on a flat surface and fill it with concrete. Gently lift the cup of concrete. If the concrete stands only a couple inches from the cups original height, it’s a good consistency. If it falls more, it is too runny.

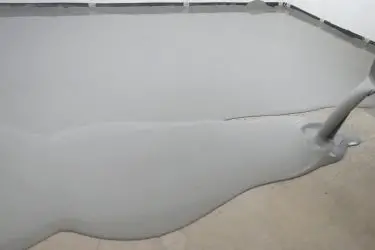

You do not want your concrete to be too dry, or too soupy. If you end up having too much water, you can add some sand. Generally, the consistency should be like thick oatmeal. Here’s an example of good concrete consistency in the video below.

Concrete powder can be made a variety of ways which can lead to many different outcomes, but hopefully these tips and ideas will point you in the right direction and get you started. Always remember to wear protective gear like gloves and eye wear when handling concrete.